Home » Products » Digital Control Vision Inspection Systems » ➤ LI-OB – LABELS, BATCHES AND BARCODES INSPECTION

➤ LI-OB – LABELS, BATCHES AND BARCODES INSPECTION

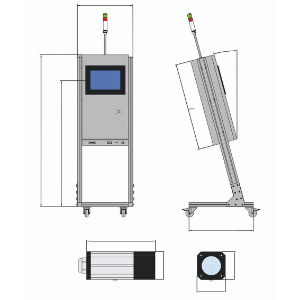

This camera system is used to inspect the correct labeling of the bottles directly inside the labeller. Using a high-resolution camera and specific illuminators, it checks the correct positioning of the label as well as its integrity and correctness. Also used for batch and barcode inspection. It can consist of multiple cameras (up to six) to control multiple labels at the same time. It can be connected to ejection systems thus giving the opportunity to discard non-compliant containers.

Key Features

• Label presence detection

• Correct positioning and integrity detection

• Rotated label detection or label with tears and folds

• Presence detection and reading of lot codes, barcodes and 2D datamatrix codes

• Detection of double writings and stains on labels

• Complete statistical management of production

• Password protected data

• Storage of all data for each format

• Easy to use touch screen interface

Specifications

• Production capacity: from 5.000 to 15.000 pieces/h (LI 515 OB). From 15.000 to 60.000 pieces/h (LI 1560 OB)

• Power supply: 230 Vac 50-60 Hz

• Power consumption: 300 W

• Protection: in accordance with EC

• Weight: 100 kg

• Display TFT 17″ Touch Screen

• Ethernet interface for connection to local networks or the internet.

Options

• Progressive ejection system REJ-8-V

• Ejection System REJ-1-V

• Remote assistance service and remote management of the system.

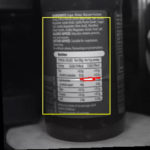

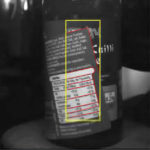

Examples of Rejects