Home » Products » Digital Control Vision Inspection Systems » ➤ CMTL – CAP AND LEVEL INSPECTION

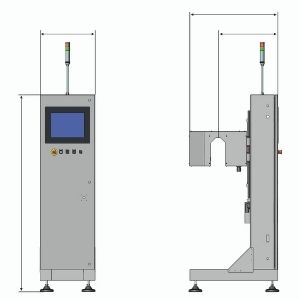

➤ CMTL – CAP AND LEVEL INSPECTION

Vision System able to verify correct product filling inside glass, PET and HDPE containers of any shape and color. The system does also a complete cap inspection both on cork, plastic and metal cap. It is possible do also a complete inspection of a stelvin cap. It can handle a large amount of codes and recipes. Automatic change over thanks to the motorized head of reading. Technologically advanced, is compact and easy to use.

Key Features

• Min and Max filling level measure

• Presence and position inspection for cork cap

• Closure inspection of stelvin cap

• Inspection of the warranty ring integrity

• Complete statistical management of the production

• Automatic motorized changeover

• Data protection by password

• Storage of all settings and parameters for each format

• Remote assistance via teamviewer

• Intuitive touchscreen interface

Specifications

• Production capacity: from 5.000 to 15.000 pieces/h (CMTL 515 NT). From 15.000 to 40.000 pieces/h (CMTL 1540 NT)

• Power supply: 230Vac Monophase + Earth

• Power consumption: 0,5 kW

• Protection: in accordance with EC

• Weight: 100 kg

• Display TFT 10″ Touch Screen

• Ethernet interface for connection to local networks or the internet.

Options

• Aluminum screw closure inspection

• Expulsion systems

Example of Rejects