Home » Products » Digital Control Vision Inspection Systems » ➤ CBF – EMPTY BOTTLES INSPECTION

➤ CBF – EMPTY BOTTLES INSPECTION

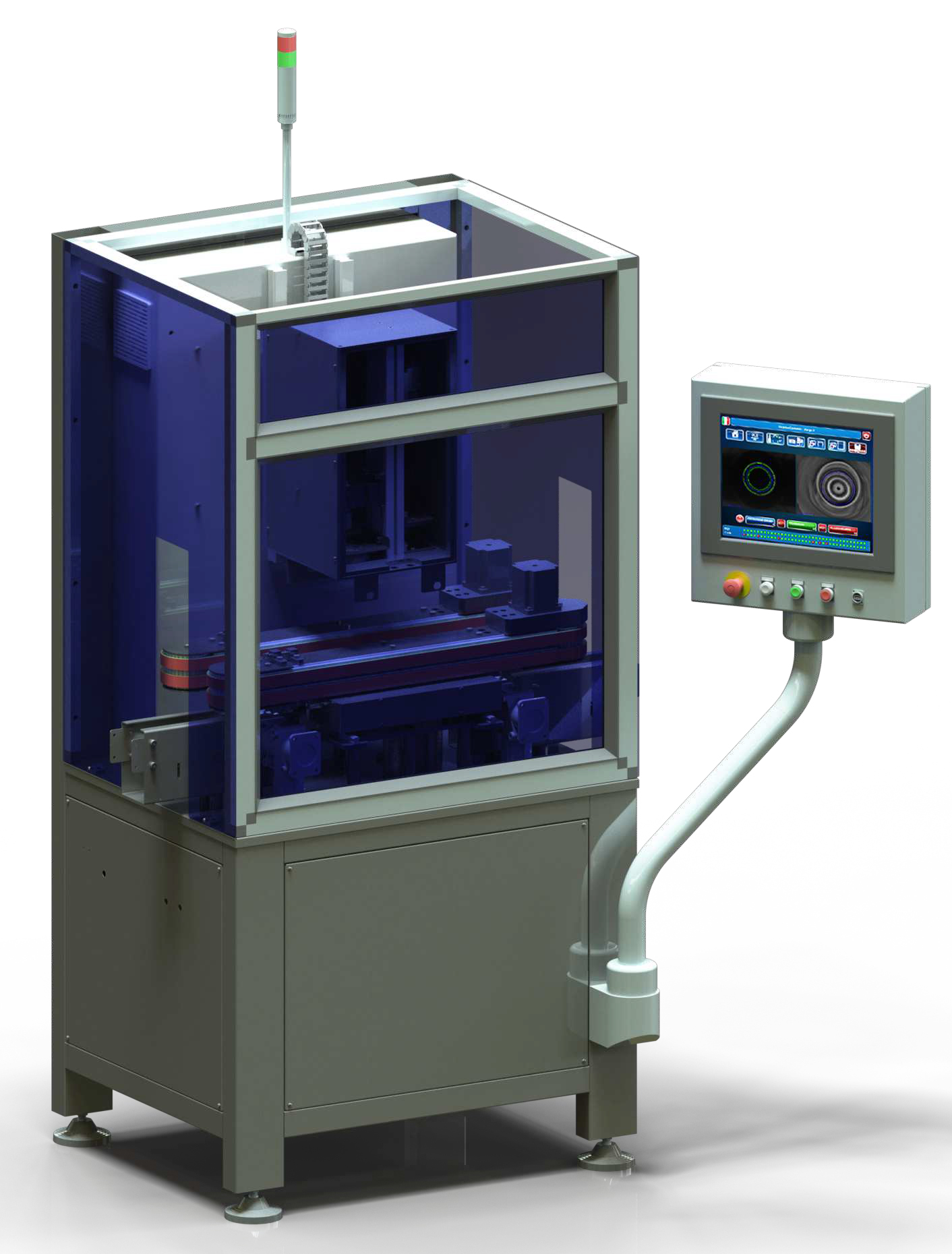

This system is used for the inspection, before filling, of the bottom and the bottom of bottles or containers in glass and PET. The camera system inspects the mouth of the bottle for cracks or abrasions. It also inspects the bottom of the container for any foreign objects or cracks. It is able to manage a large amount of codes and recipes. The system can be connected to ejectors (such as the REJ-8-V) thus giving the possibility to realize separate ejectors for the various causes of rejection.

Key Features:

• Complete inspection of the bottle end

• Break or abrasion detection

• Bottom foreign body detection

• Complete statistical management of production

• Motorized automatic format change

• Password protected data

• Memorization of the settings of each format

• Remote assistance via internet

• Modular design to facilitate any upgrades

• Intuitive touchscreen interface

Specifications

• Production speed: from 5.000 up to 15.000 pieces/h (CBF 515 N). From 15.000 up to 40.000 pieces/h (CBF 1540 N)

• Power supply: 230Vac 50-60 Hz + Ground

• Power consumption: 800 W

• Protection: in accordance with EC

• Weight: 450 kg

• Display TFT 17″ Touch Screen

• Ethernet interface for local network or internet

Options

• Expansions for the inspection of all the surfaces in empty bottles

• Progressive diverter REJ-8-V

• Tele-Assistance service remote management of system

Examples of Rejects