Home » Products » Digital Control Vision Inspection Systems » ➤ CE – 360° LABEL INSPECTION

➤ CE – 360° LABEL INSPECTION

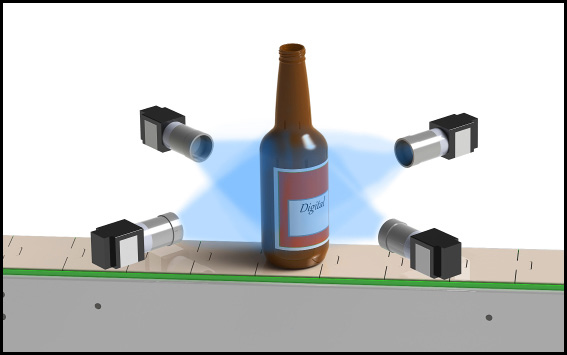

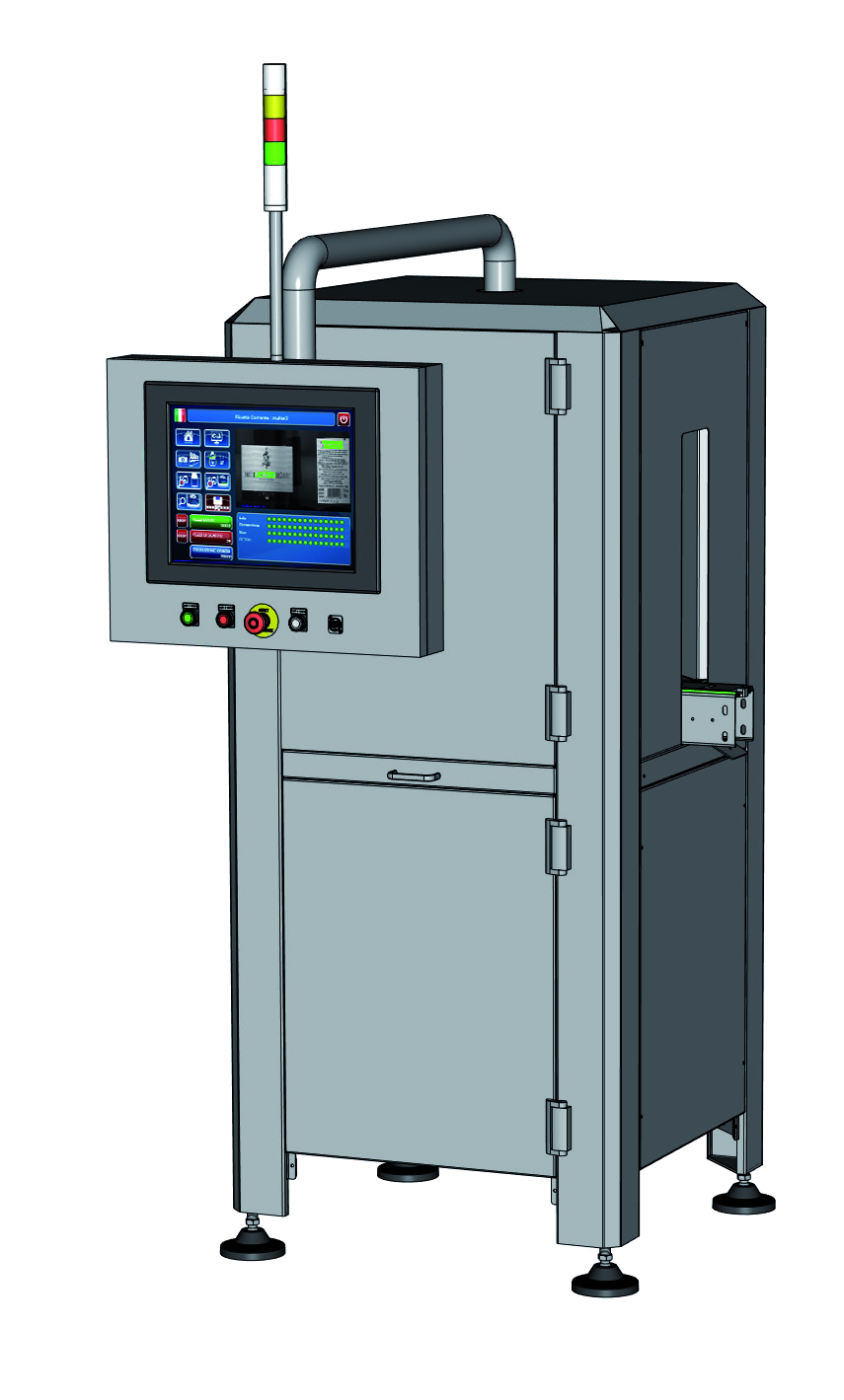

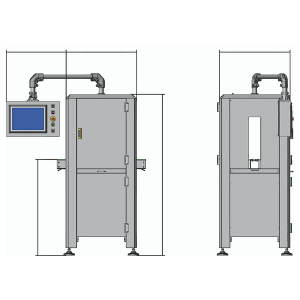

This vision system checks the correct labelling or decoration of bottles, cans or others containers to 360°. It’s an autonomous system and can be located in any bottling line before packing machine. It can handle a large amount of codes and recipes. The system checks the corresponding correct format in production, placement, orientation and integrity of all labels and seals. This vision system solves every problem about check of product labelling and ensures the best image to the packed product.

Key Features

• Detect label presence

• Detection correct positioning and integrity

• Detection label inclined

• Complete statistical management of the production

• Data Protection by password

• Storage of all settings and parameters for each format

• Remote service connection via the internet

• Modular design for easier upgrade of the system

• Intuitive touchscreen interface

Specifications

• Production capacity: From 5.000 up to 15.000 pieces/h (CE 515 N). From 15.000 up to 40.000 pieces/h (CE 1540 N)

• Power supply: 230 Vac 50-60 Hz

• Power consumption: 800 W

• Protection: in accordance with EC

• Weight: 230 kg

• Display TFT 17″ Touch Screen

• Ethernet interface for connection to local networks or the internet.

Options

• Expansion to check lot and barcode

• Progressive diverter REJ-8-V

• Remote management of system for help online.

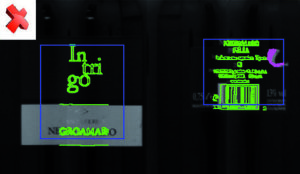

Example of Rejects