Brochure:

![]() Speed-Coat Applicator

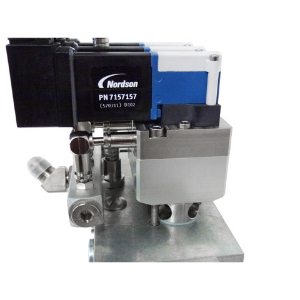

Speed-Coat Applicator

Home » Products » Nordson Adhesive Dispensing Systems » Non-Woven » Slot Coating Applicators » SPEED-COAT APPLICATOR

SPEED-COAT APPLICATOR

The Speed-Coat applicator meets high-speed intermittent and continuous production needs with accurate hot melt adhesive delivery.

The flexible design allows custom configuration for specific coating requirements. Smaller than comparable slots, the Speed-Coat applicator fits easily on production lines.

Features and Benefits

• Optimized snuff-back control module supports increased line speeds and delivers precise adhesive cutoff, minimizing contamination between patterns.

• Quick-change module and filter assemblies maximize productivity by cutting replacement time in half.

• User-friendly nozzle design simplifies applicator setup and provides application quality when web routing or web tension is not optimized.

• Self-cleaning nozzle minimizes contamination and clogging during application, maximizing uptime.

• Integrated module and applicator body deliver the industry’s best response time.

• Precision manufacture delivers exceptionally uniform distribution across the web.

• Optional anti-stick coating simplifies applicator maintenance and allows processing of reactive hot melt adhesives.

• Recirculation modules are available for producing long gaps between patterns and keeping adhesive circulating during machine stops.