Home » Products » LPMS Low Pressure Molding System » BETA 300 – SIDE INJECTION TABLE TOP MACHINE

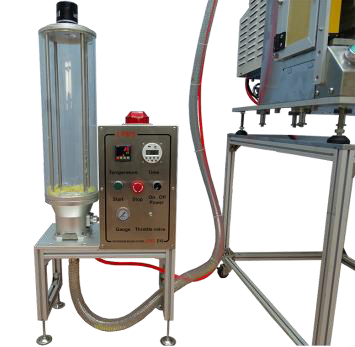

BETA 300 – SIDE INJECTION TABLE TOP MACHINE

The Beta 300 is a high-volume production capable machine that comes in a small footprint, which can be inserted into any production line. The integrated 7L Melt-on-Demand tank, and advanced safety features makes it perfect for local manufacturing.

Additional options of 2 tonne clamping force and enlarged work area can enable the Beta 300 to increase its capability even further, performing to the level of more advanced equipment.

Features

• Compact design with 3-liter melting tank integrated with machine.

• Equipped auto f eeding system and dryer machine enhance productivity.

• User friendly interface, 5 ” Touch screen operator with multi language PLC.

• Individual temperature control of tank and injection gun.

• Over temperature alarm and automatic heating stop functions.

• Safety light curtain and two photoelectric switches to protect workers during the operation.

• Products ejection system.

• Melt-on-demand tank is optional

Specifications

• Operating temperature: Ambient up to 250°C

• Melting Tank: Melt on demand 7L x 1

• Clamping force: 1.2T

• Electrical connection: 200~240VAC/1 Phase/50Hz

• Power input: 5 kW

• Min air pressure: 0.5 MPa/73 Psi

• Footprint: 740mm x 950mm

• Mould set size: 180mm x 100mm x 150mm/16kg

• Max Mould Set Size: 250mm x 120mm x 150mm