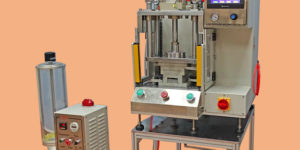

Home » Products » LPMS Low Pressure Molding System » BETA 370 – SIDE INJECTION SHUTTLE TABLE COMPACT MACHINE

BETA 370 – SIDE INJECTION SHUTTLE TABLE COMPACT MACHINE

The Beta 370 is a tabletop, shuttle table machine which allows high volume production. This machine offers the best of both worlds, with increased throughput capability, coupled with a small footprint.

Additional guarding and safety features are provided to ensure ease of use and operator safety. This machine is particularly suitable for high volume producers of a single part.

Features

• Shuttle table design one upper mold serves two bottom molds, which increases throughput and is safe for workers.

• 7-liter melting tank integrated into machine without hose.

• LPMS specially designed melt on demand tank can melt down the resin swiftly and evenly.

• Injection pressure range 1~50kg, which can be controlled by the pneumatic safety valve. LPMS also have option like electronic safety valve, which means the injection pressure can be set more precisely from the PLC.

• The gear pump is made of hard-wearing material which is stable maximum shot size is 5. 8 g/s.

• Modular injection system for ease of service.

• Two temperature control zone work independently.

• Over temperature alarm, automatic heating stop heating functions are included.

• Light curtain and photo electricity sensor buttons protect workers during the operation.

• Mold is easy to install due to LPMS standard mold base.

• Ejection system is equipped.

• Optional: Dual dispensing control system.

• Optional: Auto feeding system and dryer machine enhance productivity.

Specifications

• Operating temperature: Ambient up to 250°C

• Melting Tank: Melt on demand 7L x 1

• Clamping force: 1.25T

• Electrical connection: 200~240VAC/1 Phase/50Hz

• Power input: 4.5 kW

• Min air pressure: 0.5 MPa/73 Psi

• Footprint: 990mm x 874mm

• Mould set size: 180mm x 100mm x 150mm/16kg

• Max Mould Set Size: 250mm x 120mm x 150mm