Brochure:

![]() TrueCoat FS-PW

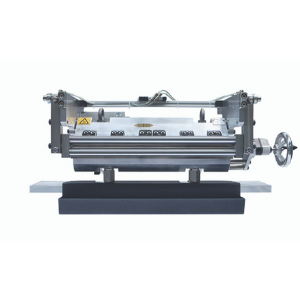

TrueCoat FS-PW

Home » Products » Nordson Adhesive Dispensing Systems » Product Assembly » Profile Wrapping Applicators » TRUECOAT FS-PW

TRUECOAT FS-PW

TrueCoat FS-PW slot applicators combine consistent, reliable performance with application flexibility toimprove product quality and production efficiency. The TrueCoat FS-PW applicator can apply a variety of adhesives in continuous operation to a wide range of substrates, including paper, veneers, foils, or films. These coated substrates are then applied to profiles in many different shapes and materials for a variety of woodworking and building/construction applications.

The TrueCoat FS-PW applicator delivers a consistent application of adhesive to the web in both cross-web and machine directions. Application (add-on) weights and coating width, using a patented coating width adjustment design, can be adjusted even during production.

Several configurations are available to meet specific production requirements. Hand wheels can be positioned on either the left side or the right side for single-side adjustment configurations. Or two hand wheels can both be located on either the left or right side for dual-width adjustment from the center of the applicator.

Benefits

• Optimized, uniform adhesive distribution yields high product quality and reduces adhesive consumption.

• Closed design protects adhesive from contaminants and moisture, particularly beneficial with reactive polyurethane (PUR) adhesives.

• Quick-exchange nozzles, filters and solenoids make maintenance faster and increase machine uptime.

• Specially designed, compact body fit allows installation into tight spots and supports better web routing.

• High production flexibility with adjustable application(add-on) weight and coating width.

• Coating nozzle geometry with increased lifetime due to enhanced contact surface.

• Simple, no-hassle installation and set-up.