Brochure:

![]() PureFlow Hose

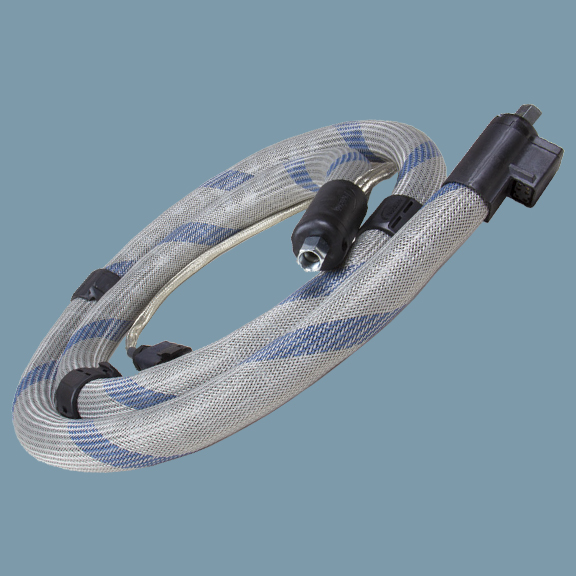

PureFlow Hose

Home » Products » Nordson Adhesive Dispensing Systems » Packaging » PUREFLOW HOSE

PUREFLOW HOSE

PureFlow hoses reduce the effects of adhesive and fluid degradation, such as charring, curing, discoloration and odor. Typical hot melt hoses experience shortened service life due to gradual material buildup on the inside throughout use. In many situations, PureFlow hoses can double the average useful life of a hose by keeping fluid pure and the interior of the hose clean. Additionally, RediFlex II mounts, which come with the T Style 9/16″ and TC-9/16″ hoses, improve routing and hanging to further increase hose life. Aramid insulation inside the hose maintains a consistent temperature, improving thermal efficiency and adhesive flow.

Features

• Reduced material degradation—such as curing, charring, discoloration and odor—supports high-performance, demanding environments

• Compatible with standard hot melt adhesives, reactive hot melt adhesives and most heated fluids

• Integrated hangers (on 9/16″-styles only) prevent damage and downtime caused by compression and sharp bending

• Easy snap-on installation enables flexible hose hanging, routing, pairing and keeps hoses off of floors

• Hangers include routing provisions for solenoid cable and air tubing

• Make-first/break last electrical connections and separate, parallel ground path

Benefits

• Maximizes material performance by reducing adhesive and fluid waste due to degradation and contamination

• Minimizes char, resulting in fewer nozzle clogs

• Helps prevent stringing caused by hose cool spots that can reduce adhesive temperature

• Reduces downtime and maintenance costs associated with frequent hose replacements

• Robust and durable for virtually any plant environment