Brochure:

![]() Pro-Meter S Gun

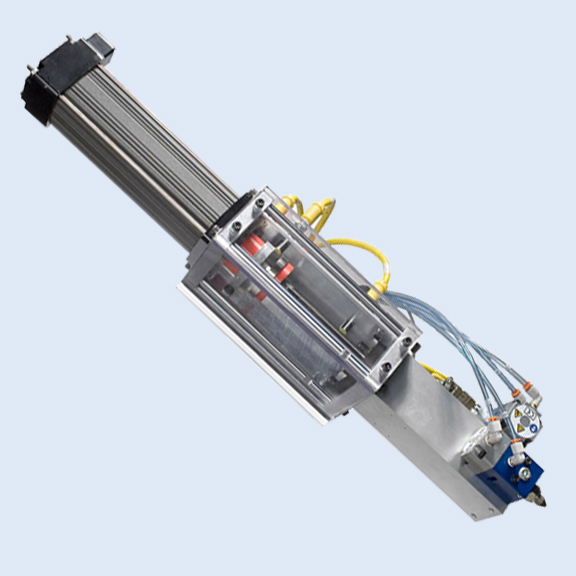

Pro-Meter S Gun

Home » Products » Nordson Industrial Coating Systems » Automotive/Aerospace Assembly Solutions » PRO-METER S GUN

PRO-METER S GUN

The Nordson Pro-Meter S combines shot meter technology with proportional control to provide precise, repeatable deposition and efficient material usage. A uniform amount of material is applied as the robot accelerates and decelerates along its programmed path via an analog input signal. This precise flow control provides better adhesive bead profiles and faster cycle times.

The material cylinder of the Pro-Meter S system is filled by positive pressure from a Nordson Rhino bulk unloader to ensure positive material refill and eliminate “empty dispenses”. The first-in, first-out material flow eliminates dead spaces for material to pack out. In turn, the on/off gun dispenses the material with consistent bead profiles regardless of changing robot speeds for excellent product quality.

Features and Benefits

• Linear servo actuator and positive displacement meter provide accurate volume and flow rate control, regardless of changing material characteristics or robot speed.

• Flow-through material porting design reduces “packing out” of filled materials within cylinder, helping to reduce nozzle plugging and maintenance.

• Compact integrated design allows for point of dispense mounting of unit, resulting in superior response time to speed change commands.

• Quick-change packing cartridges facilitate easy access for on-line routine servicing and reduced maintenance costs.

• Auto-Flo valve technology inlet/outlet valves provide accurate deposition and control with sharp material cut-off for maximum performance and cartridge-style maintenance.

• Extrude, stream or swirl capability provides flexibility to meet application requirements.

• Multiple meter sizes available to meet specific application volume and cycle time requirements.

• Optional integrated temperature conditioning – either 120V or 240V electrically heated units or water traced units are available – provides internal control of material temperature to the point of dispense.