Brochure:

![]() DPW Series

DPW Series

Home » Products » Nordson Adhesive Dispensing Systems » Product Assembly » Profile Wrapping Applicators » DPW SERIES

DPW SERIES

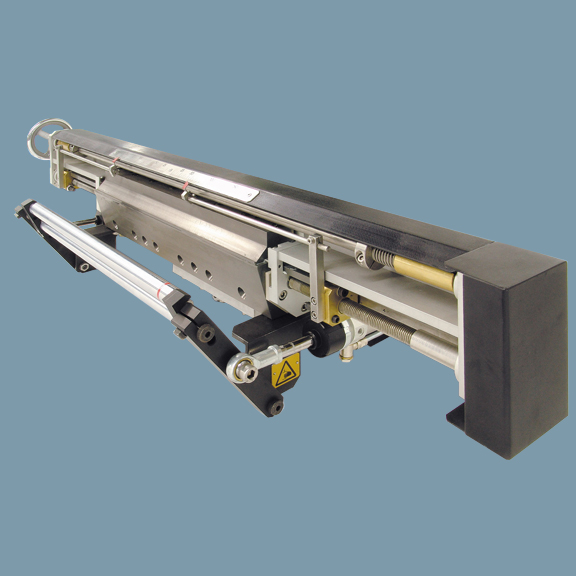

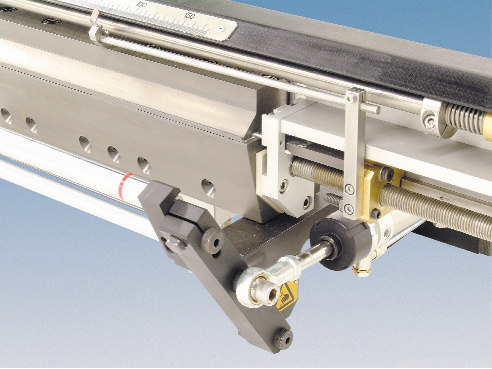

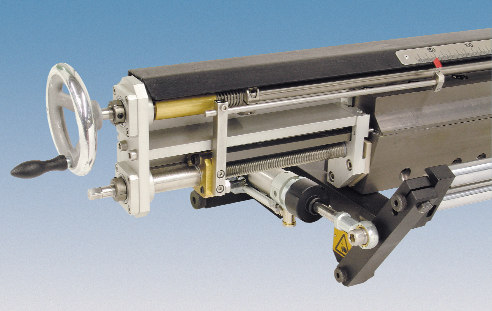

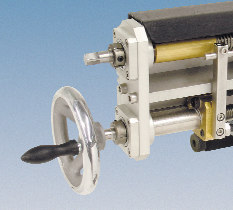

The DPW series application heads are designed to apply adhesive to vinyl, veneers, paper or other materials that are then immediately adhered to profiles or plates of varying shapes and materials. The application width can be adjusted separately from the right or left side, beginning at the center of the application head.

DPW technology offers significant advantages over the traditional method of roll application. The closed coating system – consisting of the DPW application head, tank or bulk melter, and heated hoses – is particularly well suited for complex processing of reactive polyurethane adhesives (PUR) as well as other hot melt adhesives. The closed system helps provide high quality adhesion and substantially reduces cleaning.

Precise metering with gear pumps and exact adhesive temperature control help reduce adhesive consumption and improve product quality.