Brochure:

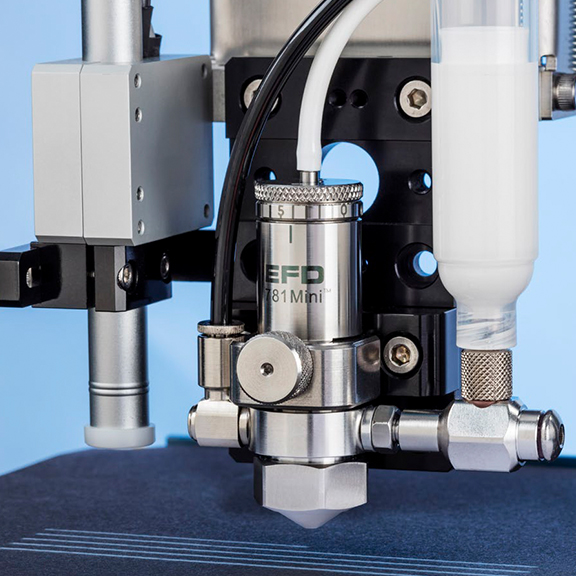

![]() 781 Mini Spray Valves

781 Mini Spray Valves

Home » Products » Nordson Engineered Fluid Dispensing Systems » Dispensing/Spray Valves » 781MINI SPRAY VALVES

781MINI SPRAY VALVES

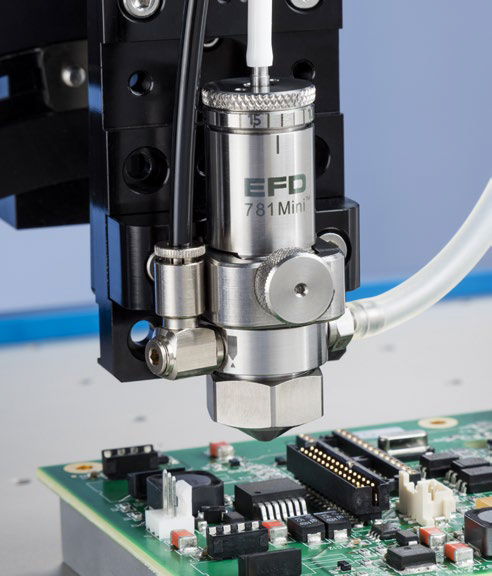

The 781Mini precision Low Volume, Low Pressure (LVLP) spray valve features a patented design that directs nozzle air pressure more consistently, for a more uniform spray pattern. This delivers greater accuracy and edge definition in applications of low-to-medium viscosity fluids such as activators, coatings, greases, oils, inks, liquid fluxes, silicones, and solvents.

It also features a 60% smaller form factor than conventional spray valves, allowing it to spray in tighter spaces and at more complex angles. Ideal for automated assembly processes, the valve’s smaller dimensions allow multiple valves to be mounted per fixture plate for greater overall throughput.

Features

• 60% smaller form factor than conventional spray valves

• Precision spray control. Consistent spray patterns as small as 1 mm (0.04″) in diameter

• High transfer efficiency without overspray or airborne mist

• Adjustable fluid flow rate and nozzle air

• Zero dead fluid volume for reduced fluid waste

• Easy-to-use, low maintenance design

Benefits

• Smaller spray patterns than could previously be achieved

• Improved spray pattern uniformity provides better accuracy and edge definition

• Smaller form factor allows for dispensing in tighter spaces, creating new manufacturing opportunities

• QR (Quick Release) clasp allows for quick, tool-free serviceability, minimizing downtime

• 360° rotational fluid body provides flexible positioning for faster setup

• Lightweight construction reduces tabletop automation motor and belt wear

• Modular design lowers cost of ownership