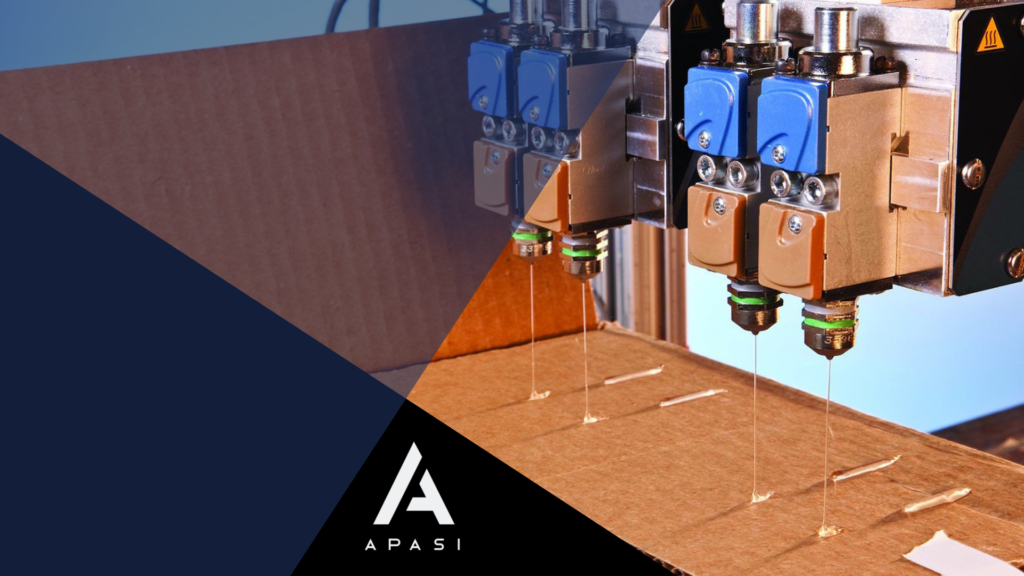

In today’s fast-paced manufacturing environment, efficiency, precision, and reliability are paramount. One of the key technologies driving these factors is automated adhesive dispensing systems. These systems revolutionize the way adhesives are applied, providing numerous benefits across various industries. In this article, we will explore the advantages of automated adhesive dispensing equipment and how they can enhance your manufacturing processes.

Enhanced Precision and Consistency

Automated dispensing solutions ensure precise and consistent application of adhesives. As a result, this eliminates the variability associated with manual application, resulting in better product quality and reduced waste. The precision of automated systems ensures that each application meets exact specifications, which is crucial for industries requiring high levels of accuracy.

Increased Production Speed

Automation significantly boosts production speed. Compared to manual

dispensers, automated adhesive dispensers can operate continuously without the

need for breaks, unlike manual processes. This increased speed helps meet

higher production demands and reduces lead times, allowing manufacturers to

keep up with market demands and reduce time-to-market.

Cost Efficiency

Automated systems reduce material waste by applying the exact amount of adhesive needed for each application. This precision leads to significant cost savings over time. Additionally, the reduction in labor costs associated with manual adhesive application can be substantial, further improving the overall cost-efficiency of the manufacturing process.

Improved Workplace Safety

Manual adhesive application can expose workers to potentially harmful

chemicals and repetitive motion injuries. Automated dispensing systems significantly

minimize human contact with adhesives, enhancing workplace safety and reducing

the risk of injuries. This creates a healthier and safer work environment.

Versatility and Flexibility

Automated adhesive dispensing systems are versatile and can be easily

integrated into various manufacturing processes. They can handle different

types of adhesives and substrates, making them undoubtedly suitable for a wide

range of applications. This flexibility allows manufacturers to easily adapt to

changing production needs with minimal retooling.

Consistent Quality Control

Automated systems provide better

quality control by ensuring that each adhesive application is identical. This

consistency is critical for maintaining high product standards and meeting

regulatory requirements. In addition, automated dispensing systems include

monitoring and feedback features to detect and correct any deviations in

real-time.

Scalability

As your business grows, automated robotic dispensing systems can easily scale to meet increased production demands. They can be configured to accommodate higher volumes without compromising on quality or efficiency, making them an ideal solution for expanding operations.

To summarize, automated adhesive dispensing systems offer numerous advantages that can significantly improve your manufacturing processes, from precision and consistency to cost efficiency and safety. By integrating these systems, manufacturers can achieve higher productivity, better product quality, and a safer work environment. As the distributor of Nordson products in various industries in the Philippines, such as packaging, food and beverages, electronics assembly, automotive, powder coating, pharmaceuticals, personal care, non-woven (diapers, wet wipes, face masks, etc.), paper converting, woodworks, aerospace, and many more, APASI is dedicated to providing cutting-edge adhesive dispensing solutions that meet your specific needs. Contact us today to learn more about how Nordson’s advanced adhesive dispensing systems can benefit your operations and help you stay ahead in a competitive market.